Laboratory Research

(LR-033) Application of Zinc Ion Embedded Nylon Antimicrobial Technology for Design Flexibility of Wound Dressings

Friday, April 28, 2023

7:15 PM - 8:30 PM East Coast USA Time

Kyoung Kim, PhD – Ascend Performance Materials; Keh Dema, MS – Ascend Performance Materials; Victor Kholodkov, MS – Ascend Performance Materials; Kevin Urman, PhD – Ascend Performance Materials

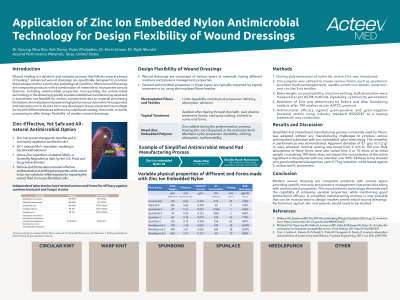

Introduction: Wound healing is a dynamic and complex process that follows several phases of healing. Advanced wound dressings are specifically designed to promote these phases and/or a particular pathological condition. Most wound dressings are composite products with a combination of materials to incorporate various features, including antimicrobial properties. Incorporating the antimicrobial technology in the dressing typically involves additional manufacturing steps and is sometimes not feasible for certain components of the dressings due to material processing limitations. A novel polymer based on high performance nylon which incorporates and maintains zinc in its ionic form was developed. It was converted into multiple forms with different features without any additional coating, chemicals, or textile processing to offer design flexibility of modern wound dressings.

Methods: Various forms, such as nanofiber, microfiber, spunbond, spunlace, needle punch non-woven, warp-knit, and circular knit textiles were produced from the novel zinc ion embedded nylon polymer. Apparent density, moisture wicking, bulk absorption, compressibility, mean-flow-pore-diameter were measured per ASTM methods. Retention of active ingredients was determined by comparing the zinc contents before and after laundering sample for a prescribed number of times as per AATCC protocol. Antimicrobial efficacy of these different forms was investigated against gram-positive and gram-negative bacterial strains using industry standard ISO20743 as a testing framework.

Results: Depending on the process used, apparent densities of different forms were varied from 0.1 g/cc to 0.2 g/cc. Vertical wicking was tuned from 0 mm to 100 mm. Bulk absorptions of these forms were also varied from 2 to 15 times of its initial weight. Similarly, compressibility and mean-flow-pore-diameter were fine-tuned. Laundering 100 times does not impact the concentration of the active ingredient in the polymer. All these forms showed very good antibacterial properties, up to 5-7 log reduction, while tested against S. aureus and K. pneumonia.

Discussion: Modern wound dressing are composite products with various layers providing specific moisture and pressure management characteristics along with antimicrobial properties. This novel polymer technology demonstrated the capability of achieving variable properties, while maintaining good antibacterial efficacy, without post processing that can be incorporated to design modern wound dressings.

Methods: Various forms, such as nanofiber, microfiber, spunbond, spunlace, needle punch non-woven, warp-knit, and circular knit textiles were produced from the novel zinc ion embedded nylon polymer. Apparent density, moisture wicking, bulk absorption, compressibility, mean-flow-pore-diameter were measured per ASTM methods. Retention of active ingredients was determined by comparing the zinc contents before and after laundering sample for a prescribed number of times as per AATCC protocol. Antimicrobial efficacy of these different forms was investigated against gram-positive and gram-negative bacterial strains using industry standard ISO20743 as a testing framework.

Results: Depending on the process used, apparent densities of different forms were varied from 0.1 g/cc to 0.2 g/cc. Vertical wicking was tuned from 0 mm to 100 mm. Bulk absorptions of these forms were also varied from 2 to 15 times of its initial weight. Similarly, compressibility and mean-flow-pore-diameter were fine-tuned. Laundering 100 times does not impact the concentration of the active ingredient in the polymer. All these forms showed very good antibacterial properties, up to 5-7 log reduction, while tested against S. aureus and K. pneumonia.

Discussion: Modern wound dressing are composite products with various layers providing specific moisture and pressure management characteristics along with antimicrobial properties. This novel polymer technology demonstrated the capability of achieving variable properties, while maintaining good antibacterial efficacy, without post processing that can be incorporated to design modern wound dressings.

.png)